The aerospace standard AS9100 Revision D was originally planned to be released in April 2014. However, this was not the case; the IAQG decided to release the English version, along with all the required IAQG language, in October 2016.

The late release of the standard, coupled with the September 2018 transition deadline date remaining unchanged, increases the pressure on organizations planning on transitioning to AS9100 Rev. D.

Let’s explore the challenges to organizations planning their transition by first understanding the changes that AS9100 Rev. D reflects; deciding on which of the other AS standards should be implemented along with AS9100 Rev. D.

AS9100 Rev. D changes

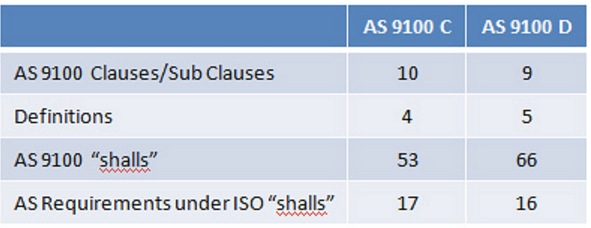

AS9100 Rev. D is built on a base of the recently revised quality management system standard ISO 9001:2015. The drivers of AS9100 Rev. D are the changes found in ISO 9001:2015, along with aerospace additions and other IAQG standards. When AS9100 Rev. D is compared to AS9100 Rev. C, it’s evident that the number of additional “shalls” in AS9100 Rev. D is 66 vs. 53 “shalls” in AS9100 Rev. C. (See figure 1 below.)

Figure A: Comparison of "Shalls" in AS9100 Rev C and Rev D

There are nine subclauses in AS9100 Rev. D vs. 10 subclauses in AS9100 Rev. C. There are two new subclauses in AS9100 Rev. D, which are 8.1.3—“Product safety” and 8.1.4—“Prevention of counterfeit parts.” However, 30 percent of the additional “shalls” were in “Measurement, analysis and improvement” in AS9100 Rev. C, and only 3 percent were in “Performance evaluation” for AS9100 Rev. D.

Product safety, counterfeit parts, and human factors are the big differences between AS9100 Rev. D and Rev. C. The subclause 8.1.3—“Product safety” has not only been added, but also appears in five additional areas of the standard. 8.1.4—“Counterfeit parts” likewise has been added and shows up in three additional areas of the standard. “Human factors” has been added to 10.2—“Nonconformity and corrective actions.” The other changes reflect movement of the clauses from the process model structure in AS9100 Rev. C to the plan-do-check-act (PDCA) structure of AS9100 Rev. D. (See Below)

Figure B: Changes to AS9100 Revision C and D.

When AS9100 Rev. D is compared to AS9100 Rev. C, the changes in the additional aerospace requirements are not as significant as the changes in the base ISO 9001:2015 standard.

Changes in ISO 9001:2015

There are 18 changes in ISO 9001:2015 compared to ISO 9001:2008. Some of the significant changes include the High-Level Structure change. Also, there is the addition of Context, Interested-party expectations, and risk-based thinking as three of the biggest changes in the standard.

Context, interested-party expectations, and objectives

“Context” is a term that has been hot in business circles during the last few years. Context, or “contextual intelligence,” has been associated with setting company strategy. The argument has been that companies need to consider the context of the organization when they design their strategy, goals, and objectives.

“Context matters." Context, has entered into our lexicon from a business perspective. An organization’s context, both internal and external, will influence the policy, objectives, and processes of the quality management system (QMS). ISO 9001 says that an organization needs to identify the internal and external issues “relevant to the purpose and the strategic direction and that affect its ability to achieve the intended result(s).” In a note, ISO 9001:2015 suggests that both internal and external issues must be developed when determining the context of the organization. The external context needs to consider issues from legal, technological, competitive, market, cultural, social, and economic environments, whether international, national, regional, or local. Internal context needs to consider issues related to values, culture, knowledge, and performance.

The organization then identifies not only customer expectations, but also interested-party expectations. ISO 9001:2015 scopes interested parties and their requirements to those that are relevant to the QMS.

Once the issues related to the context as well as interested-party expectations and requirements are identified, what’s next for the organization?

The organization uses the context and the strategic direction to formulate the quality policy and objectives (subclause 5.1.1 b). The organization also uses the context and the interested-party expectations to determine the risks and opportunities, and subsequently, the actions to address them (subclauses 6.1.1 and 6.1.2). Strategy is defined as planned activities to achieve an objective (subclause 3.35), and hence, strategic direction can be thought of as the mission and vision that define the quality policy and objectives.

Risk-based thinking

Many aerospace organizations thought that subclause 7.1.2—“Product realization risk” in AS9100 Rev. C would suffice for meeting the requirements of ISO 9001:2015. However, ISO 9001:2015’s risk-based thinking is more comprehensive; clause 6.1 is about planning risk or the risk and opportunities of not meeting “intended outcomes.”

Leadership

Another big change found in AS9100 Rev. D is the expectations and accountability of top management. Even though responsibilities can be delegated, accountability is with top management. Top management is responsible for AS9100 performance, ensuring that senior management perform their responsibilities and that AS9100 is functioning satisfactorily. In short, top management is in for a major surprise if they think that it’s “business as usual.”

In short, ISO 9001:2015 changes affect AS9100 Rev. D significantly, and implementers must understand these requirements as they plan their implementations.

Other AS9100 standards

AS 9100 Rev. D identifies 16 additional standards that can be integrated into AS9100 as various clauses are being implemented. AS9101 is another important aerospace standard relating to audits. AS9102, concerning first-article inspection, and AS9103 on variation management are both key aerospace standards to consider as well. Another standard which is critical for organizations in the aerospace industry is AS9145 for aerospace APQP and PPAP. Organizations need to adopt this standard for two major reasons: it’s required by most aerospace OEMs, including Bombardier, Air Bus, Embraer, Rolls Royce, UTC, Parker, and others; and it helps reduce on-time and quality risks in a product launch.

Transition timelines

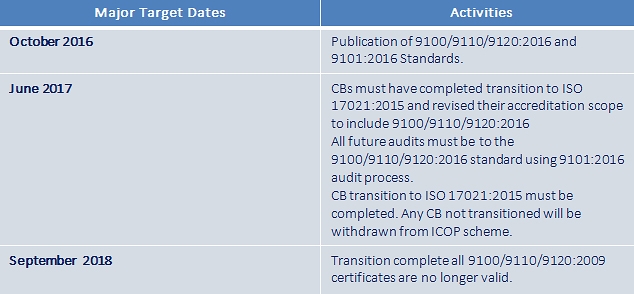

There are four key dates for AS9100-registered companies. The first is when the official AS 9100:2016 standard will be released in October 2016. The second key date is June 2017, which is the deadline past which no new AS9100 Rev. C companies will be accepted, and also the deadline for when registrars will stop using AS9100 Rev. C in surveillance audits. The third key date is September 2017, when all AS9100 companies must provide their transition dates and plans to their registrars. The final key date for AS9100 Rev. D is September 2018, when organizations are required to be registered to AS9100 or else lose their AS9100 certification.

Figure C: Major Target dates for AS9100 Revision D

Companies can start their transitions now. Organizations will need to conduct a gap assessment and formulate their implementation plans, train their implementer, auditors, and top management.